® ® Est 1960

RICHARD SMALLEY TECHNICAL SERVICES

DESIGNERS OF SPECIALIST NICHE MARKET MACHINERY

1, St Margarets Road, Bolton Le Sands, Carnforth, LA5 8EN. United Kingdom

Tel: 01524 720118 Mob: 07931681930

SPARES CUSTOM DESIGN HOME PAGE HISTORY

DESIGNS FOR SALE

® .

® .

Bright Idea runner up award winner 2003

The Altos Track system was developed (1996) by Richard Smalley F.I.Agr.E. At that time when we were manufacturing forest harvesters, it was observed that operators were having a very rough ride, as when a conventional rigid track system is used for harvesting of trees, having to pass over tree stumps, erosion gullies and rocks the machine is aggressively thrown about which is transmitted to the driver.

(1)  (2)

(2)

Photograph (1) shows the unique attack angle offering superior stability.

Photograph ( 2) Altos track oscillation at work

With Altos each track is independent to oscillate over obstacles reducing the severity of the movement of the top superstructure, hence making the ride for the driver more comfortable, with the bonus of faster tracking speed and reduced power requirement. Once the machine is stationary the chassis and the track frames automatically lock making a rigid base for the top superstructure whether a Tree harvester, Stump grinder. Wood chipper, Pile driver, Post hammer, Platform Lifts, Tree Pruner, Rock Drill, Vertical Borer, or Excavator. Stable and more positive in its operation, greatly improving output and safety at the same time keeping the tracks fully in contact with the ground. This provides an evenly distributed ground pressure, superior traction on steep gradients and minimises damage to the vegetation and environment.

(3)  (4)

(4)

Photograph (3) is Altos 40 with wood chipper on a railway embankment.

Photograph(4) Test boring machine with the ability to be angled at 28º forward and 18º left and right. Telescope to 1 metre . Tilt forward to extract hydraulically driven borer 2 metres. 360º slew

The track frames have raised front idlers and sprockets to increase the attack angle for passing over erosion gullies or logs, rocks, stumps and kerbs to stop twisting of the track. Rock guards are full length of the long track frame to stop track shedding, which greatly reduces excessive wear to the track links, with the addition of extra rollers compared to standard track frames.

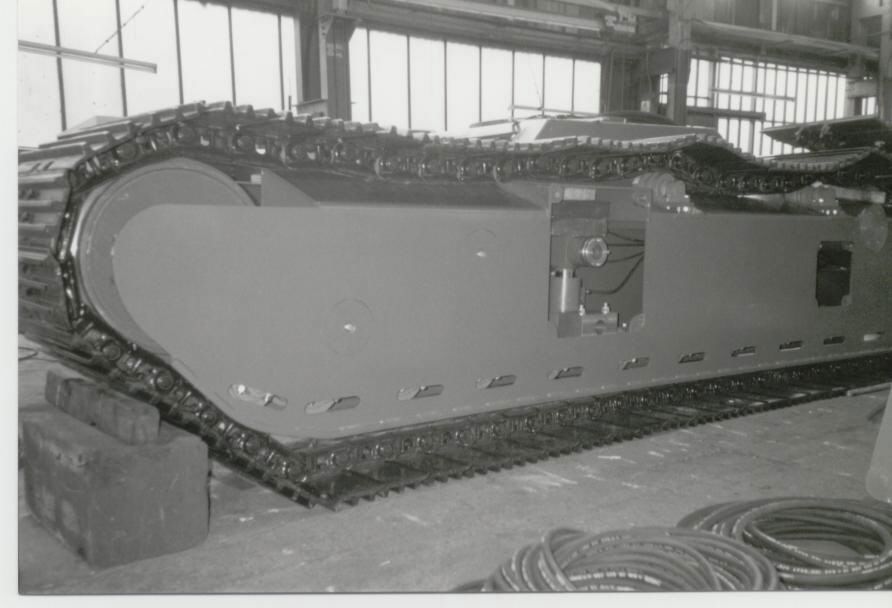

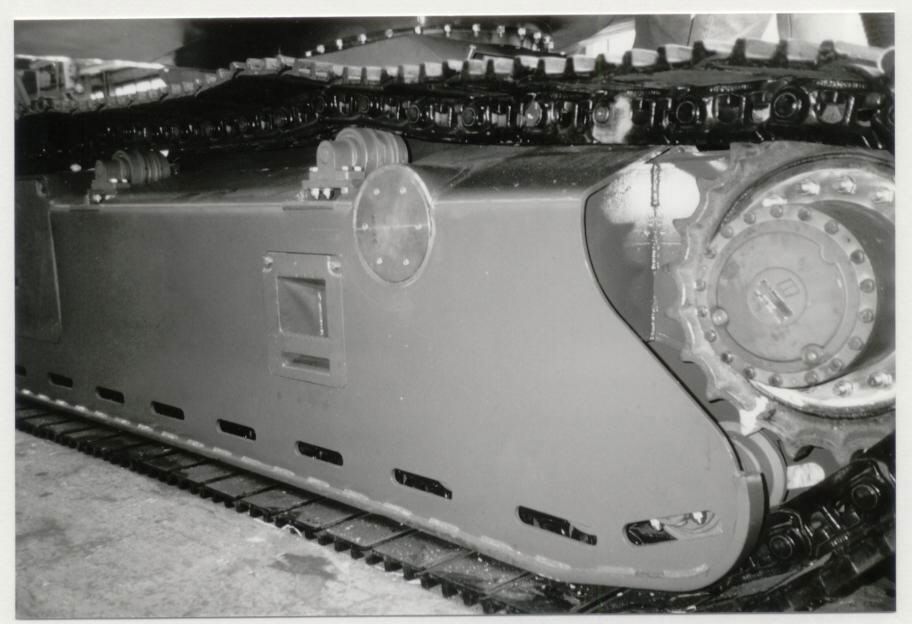

(5) (6)

(6)

Photographs (5) and (6) are close ups of the largest track frames showing raised idler and full length rock guards

Because of the greatly increased ability to travel over rough terrain and steep gradients a purpose designed addition to the Altos system, the top super structure has the ability to be levelled 28º forward and 18º to the left & Right so providing a level platform for the equipment mounted above giving the operator and attachments the ability to operate in comfort and with optimum out put. At the same time reducing the stresses and strain to the machine.

(7)

Photograph (7) Altos 27 with Vermeer wood chipper

The Altos track system is available in five sizes on steel tracks 2,500Kg 4,000Kg 8,000Kg 20,000Kg and 25,000Kg with the two smaller track frames available on optional Rubber tracks, all have been in operation and of proven design with many years of operation in the UK, Republic of Ireland, South America, U.S.A. and Africa.

(8)  (9)

(9)

Photograph ( 8) shows radio remote controlled Altos 2730 in the mountains providing a level platform with cat II 3 point linkage

Photograph ( 9) rubber tracked, radio remote controlled wood chipper RT15 with Global wood chipper

The designs for the Altos system are for sale for outright purchase with one Altos 50 (7,000Kg) complete chassis and track gear in stock.

Full set of proven detailed drawings for all five models in Auto Cad and in hard copy with technical support from the inventor and previous manufacturer / sales company. Sale of designs will include full intellectual property rights.

Available are manufacturing and in the field / sales photographs with D.V.D and film on most models including the latest radio controlled machine.

The reason this outstanding equipment is for sale, the inventor is of senior years and would be delighted to pass this experience and technology to a dedicated company appreciating quality and reliable products, to continue the success of the market in the UK and Export to be exploited because of the safety and the reduction in damage to the environment.

Ideal for a company, which has manufacturing ability, with the facility to sell to the world market.

RICHARD SMALLEY TECHNICAL SERVICES

DESIGNERS OF SPECIALIST NICHE MARKET MACHINERY

1, St Margarets Road, Bolton Le Sands, Carnforth, LA5 8EN. United Kingdom

Tel: 01524 720118 Mob: 07931681930

email: info@richardsmalleytechnicalservices.com

Contact Richard Smalley on the above number.

email: info@richardsmalleytechnicalservices.com